Complete Guide to Epoxy Flooring Types and Installation Tips

Epoxy flooring is a versatile and durable solution suitable for various environments, including residential, commercial, and industrial spaces. Comprising a combination of resin and hardener, epoxy creates a rigid plastic material when applied over concrete substrates, resulting in a seamless and resilient surface. This flooring type is renowned for its high resistance to wear, chemicals, and moisture, making it ideal for areas subjected to heavy traffic and demanding conditions.

When considering epoxy flooring, it’s essential to understand the different Epoxy Flooring Types and Installation Tips to select the most suitable option for your specific needs. Common types include self-leveling epoxy, which provides a smooth surface over existing concrete; epoxy mortar flooring, known for its exceptional strength and suitability for heavy industrial applications; and epoxy flake flooring, which incorporates colored flakes for enhanced aesthetics and slip resistance. Proper installation is crucial to maximize the benefits of epoxy flooring. The process typically involves thorough surface preparation, including cleaning and repairing the substrate, followed by the application of primer, base coat, and topcoat. Adhering to manufacturer guidelines and considering professional installation can ensure a durable and long-lasting epoxy floor.

4o mini

Overview of Epoxy Flooring Types and Installation Tips

Epoxy flooring is a highly durable and versatile flooring solution widely used in residential, commercial, and industrial spaces. It is created by combining resin and hardener, which chemically react to form a rigid, plastic-like material. This seamless and glossy surface is not only aesthetically pleasing but also resistant to wear, chemicals, and moisture, making it ideal for areas with high traffic or harsh environments, such as garages, warehouses, hospitals, and even outdoor flooring applications.

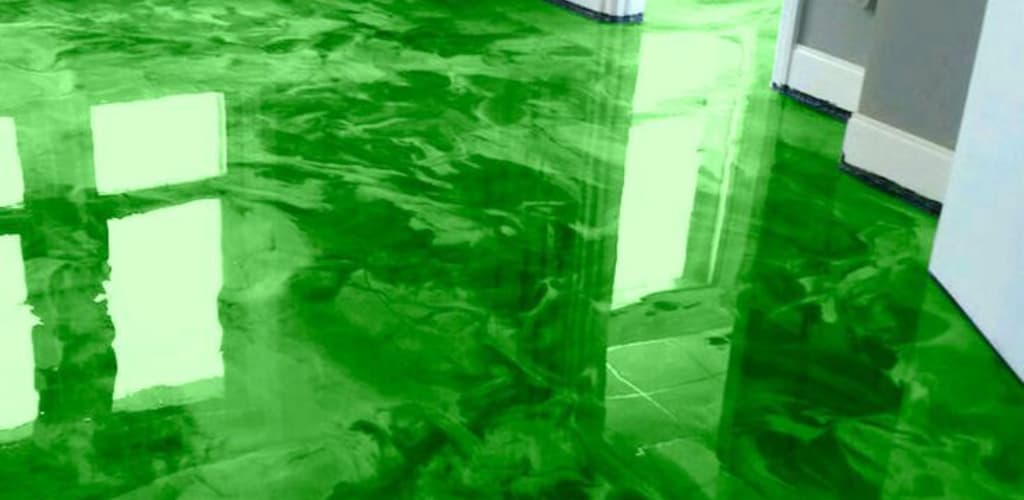

One of the key advantages of epoxy flooring is its customizable nature. Available in a variety of colors, textures, and finishes, it allows homeowners and businesses to achieve their desired look while meeting specific functional requirements. For example, anti-slip additives can be incorporated for enhanced safety, or metallic pigments can be added for a high-end, decorative effect. Additionally, epoxy flooring is easy to maintain, requiring minimal effort to keep it clean and free of stains.

Definition and Composition of Epoxy Flooring

- Epoxy flooring is a seamless surface created by curing a mixture of resin and hardener.

- The resin provides flexibility, while the hardener ensures strength and durability.

- It forms a tough, plastic-like coating that bonds firmly to concrete and other substrates.

- The flooring is available in different finishes, such as glossy, matte, or textured.

- Additives like pigments, flakes, or quartz can enhance appearance and functionality.

- Epoxy is resistant to chemicals, abrasion, moisture, and heavy impact.

- Its composition makes it suitable for residential, commercial, and industrial applications.

Historical Development and Evolution

- Epoxy resins were first introduced in the 1930s by chemists Pierre Castan and S.O. Greenlee.

- Initially used for industrial adhesives and coatings, epoxy gained popularity for flooring in the 1950s.

- Advancements in resin technology allowed for improved durability and versatility.

- The 1970s saw the incorporation of decorative additives like flakes and metallic pigments.

- Epoxy flooring expanded into residential spaces in the late 20th century due to aesthetic appeal.

- Modern formulations now include eco-friendly and low-VOC options for sustainability.

- Continued innovation focuses on enhanced durability, faster curing times, and customization.

Diverse Types of Epoxy Flooring Solutions

Epoxy flooring solutions come in a variety of types, each tailored to meet specific functional and aesthetic needs. From self-leveling floors designed for smooth, even surfaces to heavy-duty mortar systems built for industrial resilience, epoxy flooring provides solutions for a wide range of applications. Each type is formulated to address unique challenges, such as chemical exposure, high traffic, or safety concerns, ensuring optimal performance in diverse environments like warehouses, retail spaces, and healthcare facilities.

The customization options within epoxy flooring allow for greater versatility and adaptability. Different additives, textures, and finishes can be incorporated into the flooring to enhance its functionality. For instance, anti-slip coatings improve safety in wet areas, while decorative flakes or pigments elevate the visual appeal of the space. This wide range of solutions ensures that epoxy flooring can cater to the needs of both residential and commercial settings, making it a popular choice for its durability, low maintenance, and adaptability.

Self-Leveling Epoxy Floors

- Designed to create smooth, even surfaces by spreading out and filling imperfections.

- Ideal for use on old, cracked, or uneven concrete floors for a polished finish.

- Commonly used in commercial spaces like warehouses, garages, and showrooms.

- Available in various colors and finishes for aesthetic versatility.

- Resistant to abrasion, chemical spills, and heavy foot or vehicle traffic.

- Provides a hygienic, seamless surface that is easy to clean and maintain.

- Suitable for both indoor and outdoor applications due to its durability.

Epoxy Mortar Flooring Systems

- Made with a high concentration of epoxy resin and graded sand or aggregates.

- Known for its extreme durability and ability to withstand heavy loads.

- Commonly used in industrial settings such as factories and manufacturing plants.

- Provides excellent resistance to chemicals, impact, and thermal shock.

- Can be applied as a thick layer to repair and strengthen damaged concrete floors.

- Often used as a base layer for other epoxy flooring types, enhancing stability.

- Ensures a long-lasting, low-maintenance surface in demanding environments.

Advantages of Implementing Epoxy Floor Coatings

Epoxy floor coatings offer a range of benefits that make them a preferred choice for various environments. One of the key advantages is their unparalleled durability, which ensures a long-lasting surface capable of withstanding heavy traffic, impact, and wear. These coatings create a seamless, non-porous layer that adheres strongly to the substrate, enhancing the structural integrity of the floor while reducing maintenance costs. This makes them ideal for industrial, commercial, and residential applications alike.

Another significant advantage of epoxy floor coatings is their versatility and resistance to environmental factors. They can withstand exposure to chemicals, oils, and moisture without degrading, making them suitable for demanding environments such as factories, garages, and laboratories. Furthermore, their glossy finish improves lighting efficiency, while anti-slip additives can enhance safety. Epoxy floor coatings combine practicality with aesthetic appeal, offering customizable solutions that meet the needs of various industries.

Enhanced Durability and Longevity

- Creates a tough, long-lasting surface that withstands heavy foot and vehicle traffic.

- Prevents cracking and chipping, ensuring a resilient floor over time.

- Enhances the structural integrity of the underlying concrete or substrate.

- Reduces the need for frequent repairs or replacements, saving costs.

- Maintains appearance and functionality even in high-stress environments.

- Withstands temperature fluctuations and environmental wear and tear.

- Offers a reliable solution for industrial, commercial, and residential spaces.

Resistance to Chemicals and Abrasion

- Provides exceptional protection against chemical spills and corrosion.

- Withstands exposure to acids, oils, and other industrial substances.

- Resistant to scratches, scuffs, and impact damage in high-traffic areas.

- Ensures a safe and hygienic surface for laboratories, hospitals, and food facilities.

- Maintains its integrity in environments with frequent cleaning or sanitization.

- Prevents deterioration caused by moisture or chemical seepage.

- Prolongs the lifespan of the floor in demanding industrial and commercial settings.

Common Applications of Epoxy Flooring

Epoxy flooring is a versatile solution used across various industries and environments due to its durability, aesthetic appeal, and low maintenance requirements. Its ability to withstand heavy traffic, resist chemical exposure, and maintain a sleek appearance makes it ideal for both functional and decorative purposes. Whether for industrial facilities or residential areas, epoxy flooring adapts to meet the unique demands of each space, ensuring long-lasting and efficient performance.

The customizable nature of epoxy flooring further expands its applications. Different finishes, textures, and colors allow for tailored solutions that enhance the usability and look of any area. Anti-slip coatings improve safety, while decorative options like metallic effects or flakes create visually striking spaces. This adaptability has made epoxy flooring a preferred choice in a wide range of settings, from manufacturing plants to modern homes.

Industrial and Commercial Settings

- Widely used in warehouses, factories, and manufacturing facilities for its durability.

- Offers chemical resistance ideal for laboratories, pharmaceutical plants, and hospitals.

- Seamless and hygienic surface meets health and safety standards for food production areas.

- Withstands heavy machinery, forklifts, and other industrial equipment without damage.

- Improves workplace safety with anti-slip and reflective coatings for better visibility.

- Reduces maintenance downtime due to its long lifespan and easy cleaning.

- Enhances the professional appearance of offices, showrooms, and retail spaces.

Residential Spaces and Garages

- Popular in home garages for its ability to resist oil, grease, and vehicle wear.

- Creates a sleek, modern look in basements, kitchens, and living areas.

- Easy-to-clean surface keeps residential spaces free of stains and dust accumulation.

- Provides an affordable yet durable alternative to traditional flooring materials.

- Customizable finishes and colors complement a wide range of interior designs.

- Offers anti-slip options for wet areas like laundry rooms and outdoor patios.

- Increases the overall value and aesthetic appeal of residential properties.

Step-by-Step Epoxy Floor Installation Process

Installing epoxy flooring involves a detailed, multi-step process to ensure a durable, long-lasting finish. From surface preparation to the final coat application, every stage is crucial to achieving the desired results. Proper installation not only enhances the floor’s functionality but also ensures that it adheres properly and performs optimally in the long term. Following a clear, organized procedure ensures that the epoxy bonds effectively to the substrate and provides a seamless, smooth surface.

The process begins with thorough cleaning and preparation of the surface, followed by mixing the epoxy resin and hardener. Once the mixture is applied, it needs time to cure before additional layers or coatings are added. After curing, the floor is inspected, and any necessary touch-ups or finishing touches are completed. This step-by-step approach ensures that the epoxy flooring is both visually appealing and functionally resilient.

Surface Preparation and Cleaning

- Start by removing any dirt, debris, or existing coatings from the surface.

- Use a diamond grinder or shot blaster to remove contaminants and create a rough surface for better adhesion.

- Fill in any cracks or holes with an appropriate filler and smooth out the surface.

- Ensure the surface is completely dry before applying the epoxy to avoid trapping moisture.

- Clean the area with a degreaser or detergent to remove oils and grease.

- Make sure the temperature and humidity are ideal for epoxy application (usually 50-90°F and low humidity).

- Protect surrounding areas by covering baseboards, walls, and other surfaces to prevent accidental spills.

Mixing and Applying Epoxy Coatings

- Mix the resin and hardener according to the manufacturer’s instructions, ensuring a precise ratio.

- Stir the mixture thoroughly for the recommended time to avoid any air bubbles or uneven consistency.

- Apply the first coat using a roller or brush, starting from one corner and working outward.

- Ensure an even layer and avoid over-applying, as epoxy can create uneven surfaces.

- Allow the first coat to cure for the recommended time (usually 6-8 hours) before applying a second coat.

- Apply additional coats if necessary for a thicker, more durable finish.

- Finish with a clear topcoat for extra protection and a glossy, professional appearance.

Maintenance Practices for Epoxy Flooring

Epoxy flooring is known for its durability and low maintenance, but to ensure it maintains its pristine appearance and longevity, regular care is essential. Routine cleaning, periodic inspections, and timely repairs help extend the life of the floor and preserve its functionality. With the right maintenance practices, epoxy floors can retain their resilience, shine, and overall aesthetic appeal for years.

Proper upkeep involves simple tasks such as sweeping or vacuuming to remove debris, cleaning spills promptly to avoid staining, and ensuring the floor remains free from excessive moisture. Regularly inspecting the floor for cracks, chips, or wear ensures that minor issues are addressed before they lead to significant damage. When necessary, applying a new coat of epoxy can refresh the surface, keeping it functional and visually appealing.

Routine Cleaning Procedures

- Sweep or vacuum regularly to remove dust, dirt, and other debris from the floor surface.

- Mop with a mild detergent or pH-neutral cleaner to avoid damaging the epoxy coating.

- Wipe up spills immediately, especially oily or greasy substances, to prevent staining or slipping hazards.

- Use a soft cloth or mop to avoid scratching the surface during cleaning.

- Avoid harsh chemicals or abrasive cleaning tools that can wear down the epoxy over time.

- Clean the floor at least once a week, or more frequently in high-traffic areas.

- For deeper cleaning, consider using a steam cleaner or a buffer to maintain the floor’s shine.

Addressing Repairs and Recoating

- Inspect the floor regularly for any cracks, chips, or signs of wear.

- Use a patching compound or epoxy filler to repair small cracks or imperfections before they worsen.

- For larger areas of damage, grind down the affected portion and apply a fresh layer of epoxy.

- Lightly sand the surface between coats to ensure proper adhesion of subsequent layers.

- Recoat the floor every 2-5 years, depending on traffic and wear, to maintain its durability and appearance.

- Ensure the floor is clean and dry before recoating to prevent trapped moisture and adhesion issues.

- Consult with professionals for large repairs or if recoating requires a more complex process.

Potential Challenges and Solutions in Epoxy Flooring

While epoxy flooring offers numerous benefits, certain challenges may arise during installation and long-term use. Issues such as improper adhesion, bubbling, or surface wear can occur if the installation process is not carefully followed. However, these challenges can be mitigated with proper preparation, application techniques, and ongoing maintenance. By addressing common issues early and implementing solutions, the integrity and aesthetic appeal of epoxy floors can be maintained for years.

The key to avoiding problems is ensuring the correct surface preparation before installation, as epoxy needs a clean, dry, and roughened surface to bond effectively. Additionally, following manufacturer instructions during mixing and application ensures the correct curing times and application techniques. Routine maintenance, including periodic inspections and repairs, helps prevent small problems from developing into larger, more costly issues.

Identifying and Preventing Common Issues

- Improper Adhesion: Ensure the surface is thoroughly cleaned and sanded before applying epoxy to allow for proper bonding.

- Bubbling or Foaming: Avoid applying epoxy in high humidity or extreme temperatures, and mix the epoxy thoroughly to prevent air pockets.

- Uneven Finish: Apply the epoxy evenly and avoid over-applying, which can cause streaking or pooling of material.

- Yellowing or Discoloration: Prevent exposure to UV light by using UV-resistant epoxy products or applying a protective topcoat.

- Cracking or Chipping: Regularly inspect for damage, repair cracks promptly, and avoid heavy impacts on the floor.

- Moisture Trapping: Ensure the substrate is fully dry before application, as moisture can cause the epoxy to lift or peel.

- Stains: Clean spills immediately to prevent staining and use a mild cleaner to avoid damaging the epoxy coating.

Effective Troubleshooting Techniques

- Addressing Bubbling: If bubbles appear during application, sand the affected area, and reapply a thin, smooth layer to correct the finish.

- Fixing Uneven Coats: Sand the uneven surface lightly and apply a new coat, making sure to distribute it evenly for a consistent finish.

- Handling Cracks or Chips: For minor damage, fill cracks with an epoxy filler or repair kit; for larger areas, consider grinding down the affected portion and reapplying a new layer.

- Removing Yellowing: Use a UV-protectant topcoat to prevent further yellowing or discolored patches, or recoat the floor if necessary.

- Solving Adhesion Issues: If the epoxy does not bond, check the surface for contamination, clean it thoroughly, and sand it again for a better adhesion surface.

- Moisture Issues: If moisture is causing peeling, consider applying a moisture barrier layer before reapplying the epoxy.

- Cleaning Persistent Stains: For tough stains, use a non-abrasive, pH-neutral cleaner or consult with a professional for specialized cleaning solutions.

Cost Analysis of Epoxy Flooring Projects

When considering an epoxy flooring project, it’s essential to understand the factors that influence both initial installation costs and long-term value. Epoxy flooring is generally considered an affordable option compared to other high-performance flooring materials, particularly when taking into account its durability, low maintenance, and extended lifespan. However, the total cost of an epoxy flooring project can vary significantly based on factors like the size of the area, the type of epoxy used, and the complexity of the installation.

While DIY options may lower upfront costs, hiring a professional installer ensures a more accurate and reliable result, particularly in commercial and industrial applications where precision is critical. It’s also important to consider potential long-term savings from the durability and easy maintenance of epoxy floors. Despite the initial investment, epoxy flooring often proves to be a cost-effective solution when weighed against the performance, longevity, and low upkeep required.

Factors Influencing Installation Expenses

- Size of the Area: Larger areas require more material and labor, increasing installation costs.

- Surface Preparation: Extensive cleaning, sanding, or repairing of the substrate can add to the overall cost.

- Type of Epoxy: High-performance epoxy, such as self-leveling or mortar systems, can be more expensive than standard coatings.

- Customization: Decorative finishes, such as metallic effects or custom colors, can raise costs.

- Location and Accessibility: Difficult-to-reach areas or spaces with complex layouts may incur higher labor costs.

- Labor Costs: Professional installers with specialized experience tend to charge more, but this ensures a high-quality finish.

- Additional Treatments: Anti-slip coatings or UV protection can increase the cost but add extra value and functionality.

Long-Term Value and Return on Investment

- Durability: Epoxy floors can last 10-20 years or more, reducing the need for frequent replacements and repairs.

- Low Maintenance: The ease of cleaning and resistance to damage helps save on upkeep costs.

- Energy Efficiency: Glossy finishes can reflect light, reducing the need for additional lighting and lowering energy bills.

- Increased Property Value: Installing epoxy flooring in commercial or residential properties can enhance their aesthetic appeal and overall value.

- Safety Benefits: Anti-slip coatings reduce the risk of accidents, potentially lowering liability costs in commercial spaces.

- Resistant to Wear and Tear: Epoxy floors stand up to heavy foot traffic, chemicals, and physical stress, making them a long-term investment.

- Low Total Cost of Ownership: Although installation can be costly, the long lifespan and minimal maintenance make epoxy flooring a cost-effective solution in the long run.

Environmental Impact of Epoxy Flooring

As the demand for eco-friendly building materials rises, the environmental impact of epoxy flooring has become a significant consideration. While epoxy floors are known for their durability and low maintenance, traditional epoxy formulations often include volatile organic compounds (VOCs) that can be harmful to the environment and indoor air quality. However, the industry has evolved to offer more sustainable and eco-friendly alternatives. These alternatives focus on reducing harmful emissions, using renewable resources, and offering long-lasting solutions that minimize waste and the need for replacements.

By selecting low-VOC or water-based epoxy formulations, users can reduce the environmental footprint of their flooring projects. Additionally, the longevity and durability of epoxy floors contribute to sustainability by decreasing the need for frequent repairs and replacements. Overall, advancements in eco-friendly epoxy products make it possible to enjoy the performance benefits of epoxy flooring while minimizing its environmental impact.

Eco-Friendly Formulations and Options

- Low-VOC Epoxy: Formulated with fewer volatile organic compounds, these epoxies contribute to better indoor air quality and less environmental pollution.

- Water-Based Epoxy: A more sustainable option, water-based epoxies have a lower environmental impact due to reduced harmful chemical emissions.

- Recycled Materials: Some epoxy flooring systems incorporate recycled content, such as post-consumer plastic or rubber, reducing the need for virgin raw materials.

- Non-Toxic Additives: Eco-friendly epoxy products often use non-toxic pigments and fillers, further reducing the environmental and health risks associated with installation.

- Solvent-Free Formulations: These epoxy products do not contain harmful solvents, reducing air pollution and promoting better health during installation.

- Durable and Long-Lasting: The longevity of epoxy floors reduces the need for frequent replacements, leading to less waste and a lower overall environmental impact.

- Energy-Efficient: Glossy finishes on epoxy floors can reflect more light, potentially lowering the need for additional lighting and reducing energy consumption.

Sustainability Considerations in Epoxy Use

- Energy Efficiency: Epoxy floors can help lower energy consumption by improving light reflectivity, reducing the need for artificial lighting in commercial spaces.

- Waste Reduction: The durability of epoxy flooring minimizes the frequency of repairs and replacements, reducing waste in landfills.

- Longevity: Epoxy floors can last for decades, preventing the need for constant refurbishment and minimizing material consumption over time.

- Environmental Impact of Installation: Choosing low-VOC, water-based, and eco-friendly formulations reduces the chemical emissions during the installation process.

- Indoor Air Quality: By opting for low-VOC or zero-VOC products, installers can protect the health of workers and residents by reducing harmful fumes.

- Recyclability: Certain epoxy flooring systems are made with recyclable components, which can be reused at the end of the floor’s life cycle, contributing to a circular economy.

- Certifications: Some eco-friendly epoxy products are certified by environmental standards or organizations, providing assurance that they meet sustainability criteria.

Selecting the Right Epoxy Flooring Contractor

Choosing the right contractor for your epoxy flooring project is crucial to ensuring a smooth installation process and a high-quality finish. A skilled and experienced contractor can provide valuable insight into the best epoxy solutions for your needs, ensuring that the floor will perform optimally in the long term. Selecting a contractor with the right qualifications, experience, and reputation can make a significant difference in both the aesthetics and durability of your flooring.

When evaluating contractors, it’s important to consider their experience with epoxy flooring specifically, as this is a specialized area that requires technical expertise. By reviewing their portfolio, checking references, and ensuring that they adhere to proper installation practices, you can confidently select a contractor who will deliver reliable and professional results for your project.

Evaluating Experience and Expertise

- Years in Business: Look for contractors with a proven track record of successful epoxy flooring projects and a solid reputation in the industry.

- Specialization: Ensure that the contractor has specific experience with epoxy flooring, as it requires unique skills compared to other types of flooring installations.

- Industry Knowledge: An experienced contractor will have up-to-date knowledge of the latest epoxy materials, techniques, and industry trends.

- Certifications and Training: Verify if the contractor has any certifications or has completed formal training programs related to epoxy flooring installation.

- Compliance with Standards: Ensure that the contractor follows industry standards for safety, quality, and environmental compliance.

- Detailed Estimates: A skilled contractor should provide a clear, detailed estimate of the project, including material costs, labor, and installation time.

- Problem-Solving Skills: Experienced contractors should be able to anticipate and address challenges that may arise during installation.

Reviewing Past Projects and Client Testimonials

- Portfolio of Work: Request a portfolio or case studies showcasing previous epoxy flooring projects to assess the quality and variety of their work.

- Before and After Photos: Examine photos of past projects to see how the finished floors compare to initial conditions.

- Client Testimonials: Look for reviews or testimonials from past clients to gauge the contractor’s reliability, communication, and quality of work.

- References: Ask for references from past clients who can provide detailed feedback on the contractor’s performance and professionalism.

- Online Reviews: Check online platforms and directories for reviews to get a broader sense of the contractor’s reputation in the market.

- Reputation in the Industry: Consider the contractor’s reputation within the industry or local community for delivering high-quality results.

- Awards or Recognition: Contractors who have received industry recognition or awards for their work may have a strong track record of excellence.

Conclusion:

Epoxy flooring is a durable, cost-effective, and versatile solution for both residential and commercial spaces, offering long-lasting performance and minimal maintenance. With various types available, such as self-leveling and decorative finishes, it caters to different needs and aesthetics. Proper installation, including surface preparation and choosing the right contractor, is key to achieving the best results. Additionally, epoxy flooring provides long-term value through its durability, low maintenance requirements, and potential for energy efficiency. Eco-friendly options further enhance its appeal, making it a sustainable choice for those seeking both functionality and environmental responsibility in their flooring solutions.